This article has been reviewed in accordance with Science X's editorial processes and policies. Our editors have ensured the reliability of the content while highlighting the following attributes:

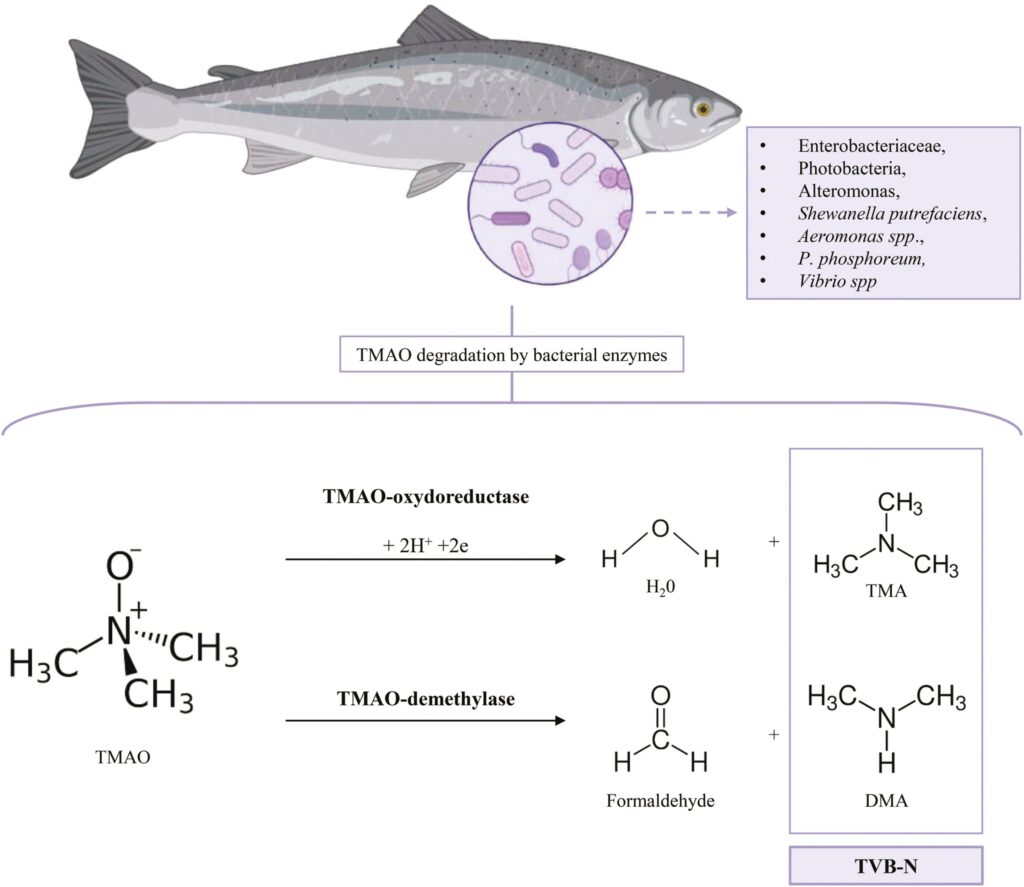

In an enzymatic process that occurs in fish, bacteria in the flesh catalyze the conversion of TMAO. TMAO is metabolized by specific bacterial enzymes, TMAO oxidoreductase and TMAO demethylase, to produce TMA and DMA, compounds known for their characteristic fishy odor. These last two are considered TVB-N, a collective measure of various nitrogenous spoilage-related compounds. Created with BioRender.com. Credit: Food Quality and Safety (2024). DOI: 10.1093/fqsafe/fyae017

× Close

In an enzymatic process that occurs in fish, bacteria in the flesh catalyze the conversion of TMAO. TMAO is metabolized by specific bacterial enzymes, TMAO oxidoreductase and TMAO demethylase, to produce the compounds TMA and DMA, known for their characteristic fishy odor. These last two are considered TVB-N, an overall measure of various nitrogenous spoilage-related compounds. Created by BioRender.com. Credit: Food Quality and Safety (2024). DOI: 10.1093/fqsafe/fyae017

Seafood is in high demand in many parts of the world, and the demand for seafood is expected to soar by 56% by 2050. Because seafood has a high moisture content and is susceptible to microbial and biochemical spoilage, it often requires extensive processing and preservation to maintain its freshness, unique composition, and flavor.

However, the seafood processing industry nevertheless produces huge amounts of waste, sometimes more than can actually be eaten. Improper waste disposal and seafood spoilage can have even more serious environmental, economic and health impacts.

Therefore, sustainable processing and preservation methods are needed to maintain the quality of seafood over the long term while minimizing the environmental and economic impacts of the waste generated.

Seafood is often preserved using traditional methods, including drying, salting, canning, fermenting, pickling, sugaring, sun drying, traditional fermentation, bottling, refrigeration and freezing. While these methods help extend the shelf life of seafood, they can also change the taste, texture and flavor of the seafood, potentially rendering it inedible.

Furthermore, the use of these methods requires strict measures to maintain hygiene and efficiency, which can incur additional costs.However, recently, several innovative physical and chemical methods have gained attention that have the potential to transform seafood processing into an economically and environmentally sustainable process.

Now, in a review article published in the journal Food Quality and Safety, researchers highlight some of the recent pioneering physical and chemical advanced technologies that can effectively mitigate seafood waste and increase productivity.

The review was co-authored by Dr Luisa Diomede, Dr Andrea Konz, Dr Enrico Davoli and Dr Carlotta Franchi from the Mario Negri Institute of Agronomic Sciences (IRCCS) in Milan, Italy, and is part of the project “ON Foods – Realigning research and innovation in sustainability, food safety and nutrition – an ON Foods initiative”.

Further explaining the rationale for conducting this study, Dr Diomede, corresponding author of the review, said: “With a mission to extend the shelf life of seafood, maintain its quality, reduce waste and minimise its impact on the environment, the seafood preservation industry is seeking innovative ways to achieve this objective.”

“The review sought to assess whether the proposed innovations address the complexities of seafood preservation to consciously and sustainably meet the surging demand for seafood.”

The researchers conducted a detailed literature search and identified 49 studies focusing on physical and chemical fish preservation techniques across 23 countries. The chemical methods they evaluated included the use of organic acids and preservatives derived from biological sources such as microorganisms, plants and animals.

Weak organic acids such as acetic acid, citric acid, lactic acid, ascorbic acid, and their sodium salts slow down the lipid and nitrogen metabolism of seafood and inhibit microbial growth, which increases the shelf life.

In addition, the use of combinations of acids can reduce the sensory, odor and taste changes associated with a particular acid. Taking into account the species-specific properties, unique composition, concentration and type of acid, the preservation of fish and shellfish can be optimized.

Preservatives derived from metabolites of microbial, plant and animal origin are becoming increasingly popular due to their safety and potential to preserve the organoleptic and nutritional properties of processed seafood. Among the various metabolites, bacteriocins and chitosan, which are generally recognized as safe, have been demonstrated to have strong biological preservative effects due to their ability to increase the shelf life and stability of seafood.

Next, researchers are focusing on physical methods that rely on non-thermal approaches, avoiding the need for temperature maintenance, which is often energy- and cost-intensive.

Unlike traditional approaches that require maintaining a cold chain or heating, cold plasma (CP), high hydrostatic pressure (HHP), and UV-C irradiation can operate effectively at room temperature.

CP, an ionized gas with distinct solid, liquid, and gaseous states, and dielectric barrier discharge high-voltage cold air plasma (DBDHVCAP) have been demonstrated to have the ability to inhibit bacterial growth and interfere with metabolic processes leading to spoilage without compromising seafood quality.

HHP is another non-thermal method to destroy spoilage-causing microorganisms and enzymes. Optimizing temperature and pressure conditions can further increase the effectiveness of this method. UV-C irradiation is another simple and effective decontamination technique that is not dependent on temperature or pH conditions. However, physical methods can accelerate lipid oxidation, so optimization of treatment conditions is required.

In brief, this review focuses on findings from diverse studies across different preservation techniques and fish species. It also highlights the benefits and challenges associated with each approach. Although new and advanced approaches are being developed, the need of the hour is to strike a balance between improving shelf life, ensuring consumer safety and satisfaction, economic feasibility and sustainability while preserving the nutritional value and flavor of the product.

“As the industry grows and advances in the future, it will remain important to address challenges and optimise fish preservation methods to ensure a sustainable, high-quality seafood supply,” Dr Diomed said.

More information: Andrea Conz et al., “Seafood Loss Prevention and Waste Reduction,” Food Quality and Safety (2024). DOI: 10.1093/fqsafe/fyae017