Qcells says it will use Lumet's fine-line metallization technology in its solar cells to achieve higher efficiency and lower production costs.

May 30, 2024 Patrick Jowett

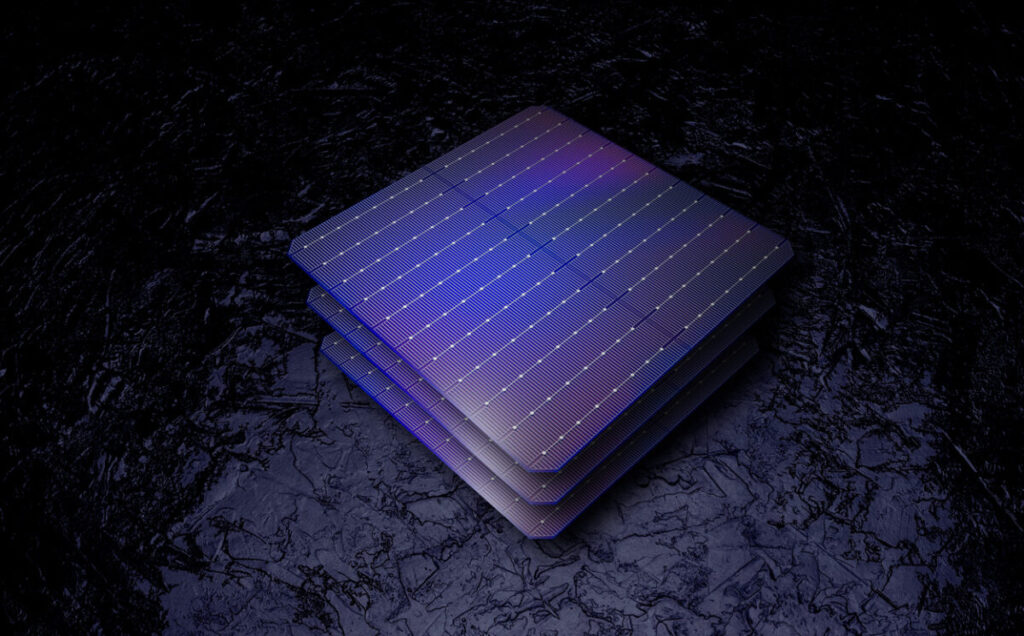

Metallized Silicon Solar Cells

Image: Lumet

Qcells has agreed to incorporate Israel-based Lumet's ultra-fine metallization technology into its solar cell line.

The metallization process, which screen-prints conductive silver fingers onto the surface of solar cells, is widely considered to be the most costly step in cell manufacturing. Efforts to reduce finger widths below the industry standard of 20 microns aim to reduce silver consumption, cost and light obscuration while simultaneously increasing efficiency.

Lumet says its technology will enable finger widths of less than 10 microns, improving cell efficiency and reducing costs. Daniel Merfeldt, Q CELLS' EVP and global chief technology officer, said Lumet's technology comes after a long evaluation.

“We see great potential for Lumet's metallization technology. The technology is groundbreaking on multiple fronts, setting records for thinnest wire, lowest cost, highest efficiency, fastest speed and smallest footprint,” Melfeld said. “Innovation and clean energy technologies will be essential to reducing global emissions and developing low-cost, accessible and reliable energy for communities around the world.”

Qcells currently operates the largest solar panel factory of its kind in the U.S. Earlier this year, the company signed a PV module deal with Microsoft and a recycling partnership with Solarcycle.

This content is copyrighted and cannot be reused. If you would like to collaborate with us and reuse any part of our content, please contact us at editors@pv-magazine.com.